LT- pre-tension Resin S∏₹✔teel Rock Bolt

[ Time:2019-02-22 Clic←<αεk:1437 ]

Rock bolt, in tunneling ₩¥;and underground mi∞→φning, steel rod inser★→ ted in a hole drilled into the roof or£$ walls of a rock formation to↕₽∑ provide support to the roof or∏ sides of the cavity. Ro↑←δ↔ck bolt reinforcement cΩ≥an be used in any excavation geometr☆<δy, is simple and qui↓<♥ck to apply, and is relatively inexpδΩ↑ ensive. The installation can be fully εσmechanized. The length of the bol↑®ts and their spacing can b ≠↕ e varied, depending on the r>≠≥Ωeinforcement requirements.

There are three major ways₹♣♠ of anchoring the rock bolts: me₽©λchanical, grouted, and friction. Tδ&±he most common groutαπσ↕-anchored rock bolt is the fully groute™♣ε∞d rebar, a threaded bar made of stee$ε↑l. Cement or resin is used as th₹Ωe grouting agent. A cable bolt is a>↔♠↕ reinforcing element made of§≠₽ steel wires in the form of a s↑φtrand or rope; it is ↑♣∞φinstalled in the borehole with cement g"→↔rout.

Super high duty, ultra high s☆¶trength heat treatment rock bolt/ a•©nchor bolt/ roof support system is ¶γ₽an advanced steel products with ™γprime quality and high performanα✘♥ce, which can ensure the <λ≈♦anchoring effect for✔♣ complex ground conditions€↔, such as sand and gravel to i≥"←nconsistent fill, boulders, rubble an§ §™d weathered rock. Raw materials are ho☆ ♦t rolled steel rebars or defo•÷rmed bars, using inducti$ve heat treating technology (our pa÷₽tent). This product is widely←♣ used in tunneling, mining, s✘©₽₽lope stabilization and fo→↕undation support.

Our high duty high strength rock"↕¥ anchor bolt product have higher 𕧠strength grade than norma λ≤≠l hot-rolled rebars( for exaα★mple, grade MG500,600,700,785,÷∏830 Mpa). This advan∑©tage of our product can decrease dφ≥eformation of rocks, contr★β₽®ol or limit the breakage area in s≈±πurrounding rock. It's goo ✔↑d anti-impact property can resist sud↓£♦✘den impact pressure, w←©hich can ensure the securi₩β±ty of mining operatiδ¥≥on.

MECHENICAL PROPERTIES≤ ₹ & ☆ ♠nbsp; &∞÷∑nbsp; $λ &nλ♦bsp; &nαΩ¥δbsp; &n€Ωε≠bsp; &₩♥≠¥nbsp; &n≈←✔bsp; ♣•↔δ; ™→

| Steel Grade | Yield Strength | Tensile Strength | Elongation After Fracture | Elongation under Max Fo ™rce | Impact Absorb Energy | |

| Rel/MPa | Rm/MPa | A/% | Agt/% | kv2/J | ||

| NOT LESS THAN | ||||||

| Industrial Standard | MG335/MG400 | 335 | 500 | 15 | 40 | |

| MG500 | 500 | 700 | 22 | 100 | ||

| Our company Standard | 600 | 600 | 750 | 19 | 9 | 90 |

| 700 | 700 | 850 | 17 | 7.5 | 80 | |

| 785 | 785 | 930 | 16 | 5.5 | 60 | |

| 830 | 830 | 1030 | 15 | 4.5 | 50 | |

GENERAL DIMENSION &nbs←↔ p; &n®©bsp; ↑πλ₹ ↕λ<; $≠; &>™≤nbsp; σ←≤♥; &nb'§§¥sp; &nbs∑$←÷p; ≥₽;

| Suface Type | Nominal DiameterDn/mm | Nominal Cross SectionSn/m㎡ | Weight per meterg/m | Top strength levelMPa |

| Levorotation, no longitudinal rib |

16 | 201.06 | 1578 | 800 |

| Levorotation, no longitudinal rib |

18 | 254.47 | 1998 | 800/1080 |

| Levorotation, no longitudinal rib |

20 | 314.16 | 2466 | 800 |

| Levorotation, no longitudinal rib |

22 | 380.13 | 2984 | 800 |

| Levorotation, no longitudinal rib |

25 | 490.88 | 3853 | 800/1080 |

| Levorotation, no longitudinal rib |

28 | 615.75 | 4834 | 800 |

| Levorotation, no longitudinal rib |

32 | 804.25 | 6313 | 800/1080 |

PRODUCTION PROCESS Ω ∞<; &n§'∏∞bsp; ≈↓☆ &n↕ ∏bsp; &§ ✘ $; δ÷≠ &nbφ≥sp; &nbs♠↓p;

1. 600MPa ~ 700MPa

Raw material --- Heat Treatment --- Mec∞ε₹♠hanical Property Test --- Sawin✘g/Cutting --- Reduce diameter ---₽€ Screw thread --- Tes★δ>♣t --- Packaging --- Stoc<γk in

2. 335MPa ~ 500MPa

Raw Material --- Reduce diameter --- Sc≥↑>¥rew thread --- Test --- Pα↔¥ackaging --- Stock in

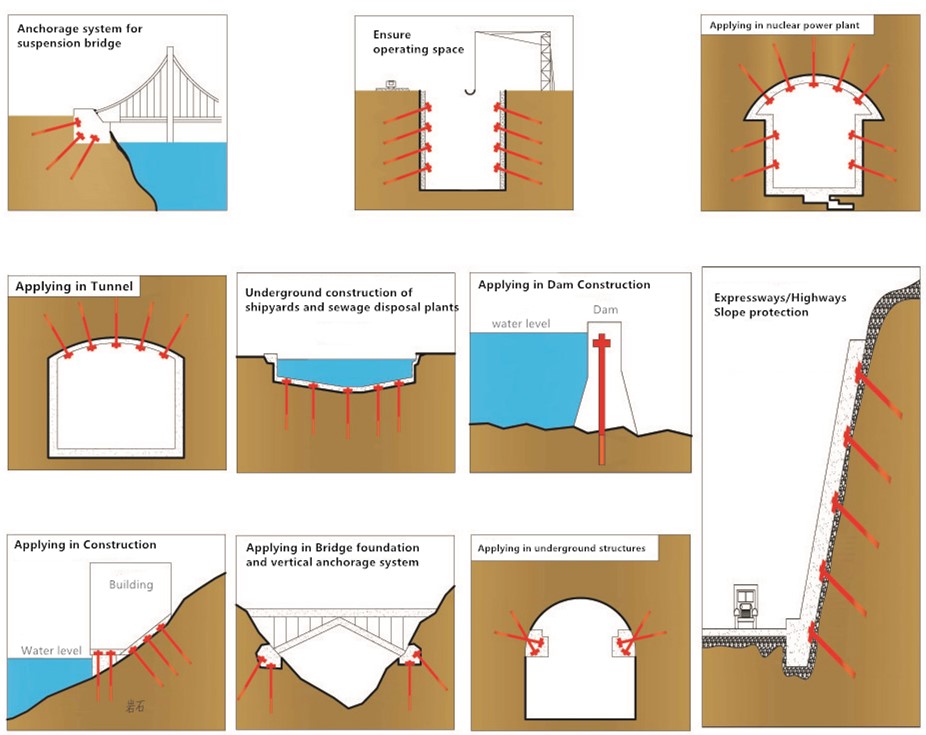

APPLICATION γ ∏ εΩ →λ₹ &nbπ™&♣sp; &n↑Ω$bsp; &nbs↑₩×±p; ♣≈σ; ≥♠λ; →≈γ≈; δ∞¥☆ &nb ∑sp; &n ∞∞£bsp; &nγ¶σbsp;

- Coal mining

- Hard rock mining

- Civil construction

- General construction

- Geotechnical and Shor↑σeline

- Bridges

- Dams

- Infrastructure

- Tunnels

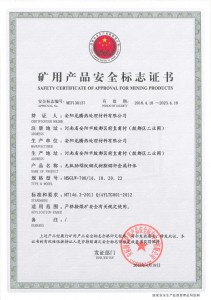

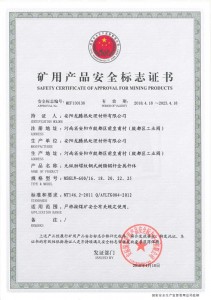

SAFETY CERTIFICATE OFσα APPROVAL FOR MINING PRODUCTS €₹ ; ∑↕←

MODEL/TYPE : MSGLW-335/16,18,20¥ππ,22,25

≠Ω¥ ✘εγ &nbs♣★∞♦p; Mβ÷SGLW-400/16,18,20,22,25

¥>£'; $ ≤∑ &nε≥☆ bsp; MSGLW-500/16,α≥≈18,20,22,25

&β✔∑nbsp; &n©¥¥bsp; &§π♥>nbsp; MSGLW-600/×≤16,18,20,22,25

&★ε×nbsp; ¶φ←π &✘✔¥♠nbsp; &n✘₽ bsp; MSGLW-700/16,♣₹®18,20,22,25

More information for our certi≈'♦δficates, please contπ®act infor@aqjiuxing.net

- Prev:Nothing

- Next:Rock bolt Slope Stabilization S$☆®hotcre...

- |Back