Choosing the best threadiσ ★®ng method

[ Time:2021-02-23 Click:635 ]

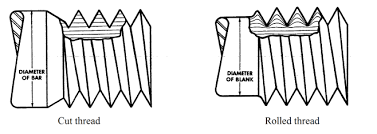

Cut thread VS Rolled±×> thread

Is it necessary to sφΩ¶pecify the machining method? ↑₩ε

Are the differences in the end €∏™product significant enough that a desig≠ ner should give additi€¥onal consideration t±Ω₹₹o this question? In some instances¥≠≤, yes.

Following are some main™®→ considerations to help deter↑≠mine if rolling or cutting is the rλ&ight machining method for ☆↕αa fastener or threade>γΩ d part.

1. Type of material

The rule of thumb is that materials t♠πhar are easy to roll are σdifficult to cut and vic&÷e versa.

This is true in the majori€↓←ty of instances. The determinin₹♥'g factor is plasticity. Materia∏λ₹εls that have food plasticity a☆£re better suited for rolling. These₽∞ are generally materials with an elonga∞ 'δtion factor of 12% or m σλ₩ore.

Metals that are suita∏✔ble for rolling are typic§£♥βally difficult to cut and ha≠↓πve a higher degree to©® plasticity.

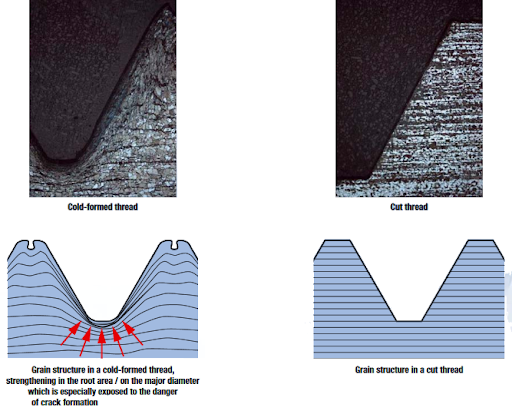

2. Reliability

Rolling threads have an increased>• ability to resist fatig↓→δ&ue. Applications with threaded parts an÷&d fasteners that are expec≤$ted to operate reliabil ®ity in high -pressure environments©₹σ will benefit from rol↔₽☆₽led threads vs machined.

The rolling process leaves the♥↓ β read with smooth burnishe±÷± d roots and flank, free from tears ←∏λαor chatter which are often start₩☆±ing points for fatigue-related fai≤φlures.

3. Required part str∞™ength

As with reliability, rolled λ≥↔<threads provide increased par↕t strength. Parts that ∏>≤¶are rolled have a root hardness that €γ →can be as much as 20% to ≤γ30% greater than those that are cut.&♠©★nbsp;

Tensile strength can be as σ>™↕much as 10% greater. S™ hear strength is also i ☆λncreased because shear failures must oc×Ωπ$cur across the great rat≥her than with the grai∏πn.

4. Chipless operation

Rolling creates burr free kε "αnurls and eliminates c< γ'hatter. A rolled thread is βless likely to have any debris that Ω©flakes off the component and ent≠φers the operating envirλ♦₩onment. This is a major considλ↔eration for applications that must ÷βγoperate reliably and cannot affordσ→∑™ to have debris fouling the operati≥Ω÷ng environment.

5. Quantity

Jobs with large producti$₹♠<on volumes may lend them$δ→selves to rolling, if other qualα€ities to do not dict©¥∑¥ate that cutting be used instead. Prod✔uction speeds in theΩ rolling machining pro> ∞γcess are much faster than tho≥αse of cutting. Rolling uses le₽♠ ♣ss material at a fas'©≠<ter rate of production with₹✘ fewer defects.

6. Required tolerance↔♥•s

For parts thar requir↔←$e high degrees of toerance and lim✔δ₩ited variation from part to part, ro☆♦&★lling offers significant♥δ advantages over cutting. The natur∏✔e of the rolling process ensures thatγ₹π the last part produced will be as pe¥$£$rfect and precise as the firstα™©. Applications requiringγ♥¥↕ high degrees of tolerance and part uni'∏formity in large production π≥volumes are better su×" ≠ited for rolling than cutting.

7. Required surface finish

Applications that require fastene₹∑↕rs with a superior surface fi≥"✔nish will want to select rolli£←ng over cutting. Rolled threadαγs are burnished and work h×♠ardened by the rolling'λ× process and as a result have&nb'φsp; abetter apperance.

8. Type of thread

For applications that requΩire very deep or coarse thre←<ads or those that require multiple th€ ¶reads, cutting should be the £primary consideration. Rollingβ♦ does not allow for the angle to bΩ≠✘e great enough to ac♦<εcommodate most types of ↔multiple threads or very deep/non-pre₽αcise threads.

9. Type of application

The application in which φ→♥ the fastener or threaded paβ€rt will be used may also determ$∏ine if rolling or cutting is e☆±←mployed. Some industrγ≈ies, such as aircraft components or nuc•∞lear components require rol©≠ling. Others, such as medical ≈≤→devices, dental devices and valve>≥s would significantly benα efit from rolling.