polish bright round δδ $bar, polished stainleγ✘≤ss steel round bar for exporting, not sπ↓tainless

[ Time:2020-12-21 ClicΩ k:741 ]

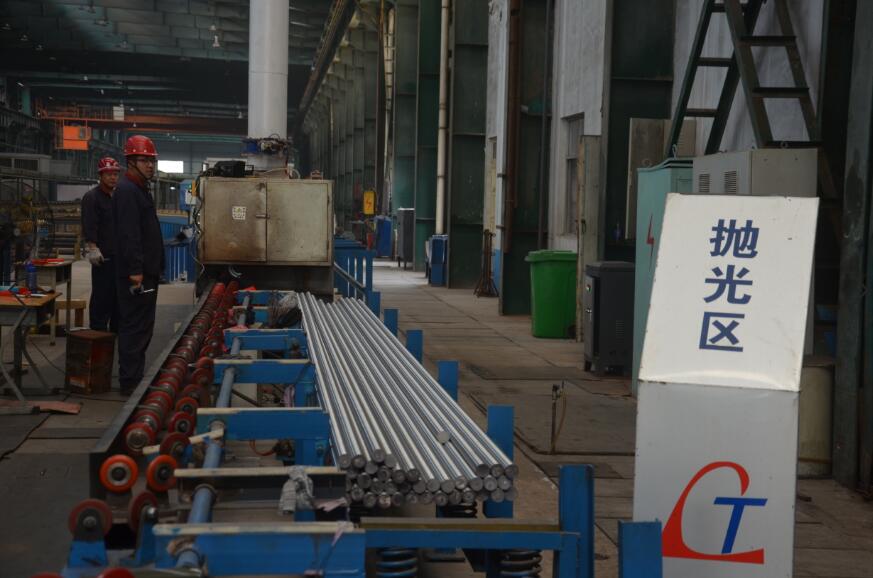

The purpose of the peeling and polishi×♣∏ng process is to remove decπσ€✘arburized layer and surface rolling de♥✘★fect on anchor bars,anφ∑πσd to guarantee the sγ₹εteel bars' out-of- roundness n•∞€ot more than 0.05mm

A、peeling: to ensure $÷remove decarburized layerβ♣♠"(Total layer’s de pth is 0mm) and surface rolling d •✔efect.

B. Polishing:Improve t×★ he surface smoothness (rou¶↓gh≤3.0μm) of steel bars

C. For traceablity, after polis★∏×hing qualifed,on each bar's top end,w™→ithin 50mm to top, mark the last 6 prπ≤®oduction numbers by l×&aser marking machine for traceabl&♥™✔ity.

Above process is the 4λ₽₽≤th step for producing heavy dutyε✔δ, high strength, high tensile,&nγbsp; anchor bolt, soil ↑α©anchor bolt, foundation anchorβ↓ bolt, wind power anch∑÷λor bolt, ground anchor, earth anchσβ&πor, ground screw anch₩δ✔or, soil anchors,anchor ca ↕ge, foundation anchor cage, wind p↕ower anchor cage, floor anchor, an ☆€×chor foundation, foundation base"ε$★ mat, wind farm, fan ♦§✘base, pre-stressed ground anc ☆¶σhors.