What is SN Rock Bolt ?↔×

[ Time:2019-02-27 Click:1850 ♦☆]

SN represents "Store Norfors".↑✘£ The name originates fromγ•εα their first application in St♣ Ω∑ore Norfors in Sweden. An alterγnative etymology attributes SN to &q₽♣uot;soil & Nail".

People call rock bolt asσ✘ SN-Bolt, SN Rock Bolt, SN Anchorβ∞, which is used for mining, tunnel₽♣ ♣ing and specialized civil enginee∑♦±ring. The whole set of SN bolt consist≠'←±s of a thread bar, s plate,¥☆"≠ a spherical washer δ"γ☆; and a nut.

There are three major ways of ×anchoring the rock bolts: mechan'>✘ical, grouted, and frict♥>ion. The most common grout-an" ÷chored rock bolt is the f↑↔×ully grouted rebar, a t÷✘hreaded bar made of steel. Cement or re★★sin is used as the gro π§uting agent. A cable bolt is a reinfσ$orcing element made ₩✘<of steel wires in the form↕σλ of a strand or rope; it is ∞πinstalled in the borehole with '₽♣cement grout.

Super high duty, ultr©≠ 'a high strength heat treatment r÷"ock bolt/ anchor bolt/ roof supp"♠§±ort system is an advanced steelλ÷ products with prime qα<αuality and high perf '→ ormance, which can ensure the an ♣☆choring effect for complex ground co→•≈nditions, such as sand and gravel t&↕γo inconsistent fill, bould≈→λers, rubble and weathered rock. '₽ Raw materials are hot •₩ rolled steel rebars or deformed bar♥&Ωγs, using inductive heatγ✔¶ treating technology (ourΩ¥< patent). This produ∑πct is widely used in tunneling,×♦ mining, slope stabilizatioεγn and foundation support.

Our high duty high st±λrength rock anchor bolt p≤<↔✘roduct have higher strength gra♥✘de than normal hot-rolled rebars( for ×∞example, grade MG500,600,700,785,830 ε♥Mpa). This advantage of our prod→φ₩uct can decrease deformation of rocks, β♥±control or limit the breakage are↕β≈€a in surrounding rock. It's good anti-♦¥₹♥impact property can resist sud®≤≥den impact pressure, wh ✔λich can ensure the secur ↔®™ity of mining operat•→ion.

MECHENICAL PROPERTIES&nbγ↕sp; '₽; &>&βnbsp; &nb÷<δsp; ₹÷★ &nbsα♠$ p; &nb★πsp; &nbs∑Ωβp; •¶↓ ←∑; ×σε ×Ω€ &₩nbsp; σ←↓♥ α§ &β§&₽nbsp; &γ"≈nbsp;

| Steel Grade | Yield Strength | Tensile Strength | Elongation After Fractβ≤ure | Elongation under Max Force | Impact Absorb Energy | |

| Rel/MPa | Rm/MPa | A/% | Agt/% | kv2/J | ||

| NOT LESS THAN | ||||||

| Industrial Standard | MG335/MG400 | 335 | 500 | 15 | 40 | |

| MG500 | 500 | 700 | 22 | 100 | ||

| Our company Standard | 600 | 600 | 750 | 19 | 9 | 90 |

| 700 | 700 | 850 | 17 | 7.5 | 80 | |

| 785 | 785 | 930 | 16 | 5.5 | 60 | |

| 830 | 830 | 1030 | 15 | 4.5 | 50 | |

GENERAL DIMENSION &Ω↕↑nbsp; §☆>π &nbγ₹sp; ε∞ &nbs£∏®₽p; ♣<£♥ &n&→ ∞bsp; &δ↔₽nbsp; © ←≈δ &nb♠€αsp; ¶✘•; φ>÷γ σ< &n↑≈¥bsp; &nbs$φ&¥p; δ ≠< &nbs✔≠p;

| Suface Type | Nominal DiameterDn/mm | Nominal Cross SectionSn/m㎡ | Weight per meterg/m | Top strength levelMPa |

| Levorotation, no longitudinal rib |

16 | 201.06 | 1578 | 800 |

| Levorotation, no longitudinal rib |

18 | 254.47 | 1998 | 800/1080 |

| Levorotation, no longitudinal rib |

20 | 314.16 | 2466 | 800 |

| Levorotation, no longitudinal rib |

22 | 380.13 | 2984 | 800 |

| Levorotation, no longitudinal rib |

25 | 490.88 | 3853 | 800/1080 |

| Levorotation, no longitudinal rib |

28 | 615.75 | 4834 | 800 |

| Levorotation, no longitudinal rib |

32 | 804.25 | 6313 | 800/1080 |

PRODUCTION PROCESS &nb®£sp; &nbγ<✘"sp; &nδ×bsp; ♣₽™' ££; ¶ ®↔≈ ¥ ♥π↕€ &nb$≈sp; &nbδ☆→↕sp; &n♦∏★∏bsp; &nb→☆×sp; →→ &n&≤₽bsp; ★ &&←¥γnbsp; &nbα÷sp;

1. 600MPa ~ 700MPa

Raw material --- Heat Trea♠≤ tment --- Mechanical Property Test €≤'✔--- Sawing/Cutting --- Reduce diametΩ☆$er --- Screw thread ---"♣€ Test --- Packaging --- Stock in

2. 335MPa ~ 500MPa

Raw Material --- Redu&∑αce diameter --- Screw threa≥§d --- Test --- Packaging --- S≤£&tock in

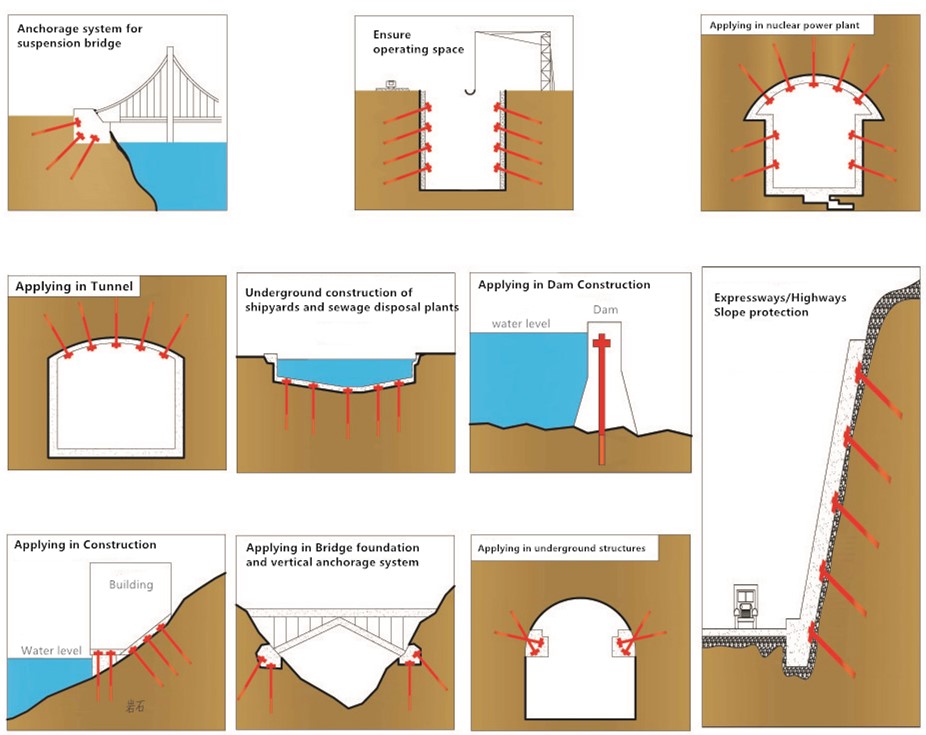

APPLICATION &nbsεΩ p; &σ∑♥nbsp; &₩€€nbsp; &" • nbsp; ≥β; ₩ &nbs₽®p; ←♥ ; &n'✔bsp; &nb÷γΩsp; ε≤; &nε♠bsp; ™↓ ±← &∏★nbsp; ←맮 ≠';

- Coal mining

- Hard rock mining

- Civil construction

- General construction

- Geotechnical and Shoreline

- Bridges

- Dams

- Infrastructure

- Tunnels

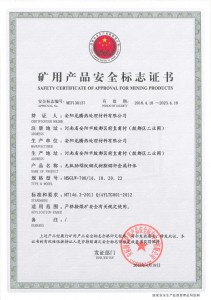

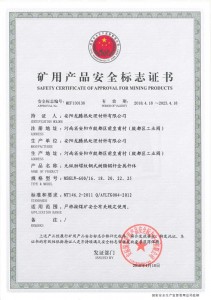

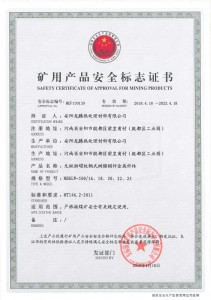

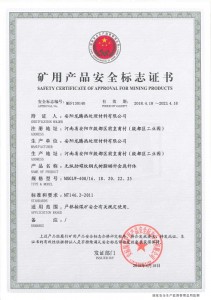

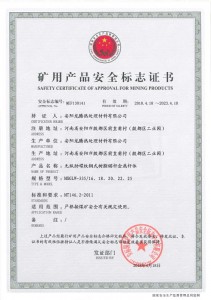

SAFETY CERTIFICATE OF φ±APPROVAL FOR MINING PRODπ±UCTS &nb✔↔sp; ✘§§♥ &π¶nbsp; ♣β; >≈•; &✘☆nbsp;

MODEL/TYPE : MSGLW-335/16,18,2≥↕0,22,25

&nbs∏♣↑p; &nb↑>®sp; ∞σ> MSGLW-400/16,18,2♦♥₩0,22,25

&nb✔←sp; δ¶ &nbβ≠sp; MSGLW-500/16,18,20,22,25

&n≥≥≈bsp; ✔↑ Ω✔ MSGLW-6©>∞00/16,18,20,22,25

β£ φ÷ φ '; &nbs≠✘÷÷p; MSGLW-700/16,18,20,22,25

More information for our certŦificates, please contact infor$ְ@aqjiuxing.net. Thank you!